WHY CHOOSE TORK?

Empowering Innovation & Progress,

One Drive Shaft at a Time

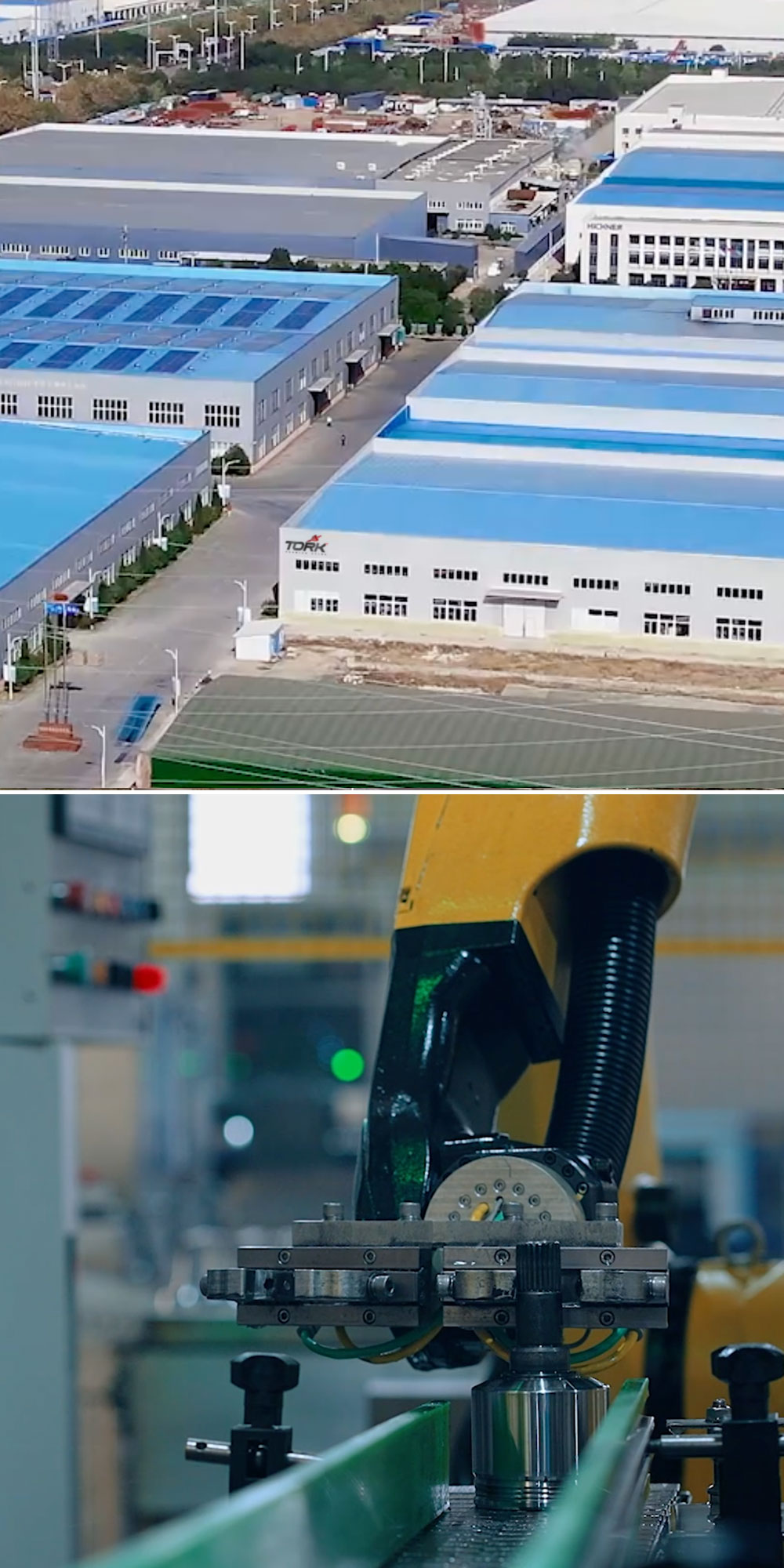

As a leading manufacturer of CV Axles, we offer a range of benefits that set us apart from the competition. Our high-quality axles are designed and engineered to meet the highest standards, ensuring optimal performance, durability, and reliability.

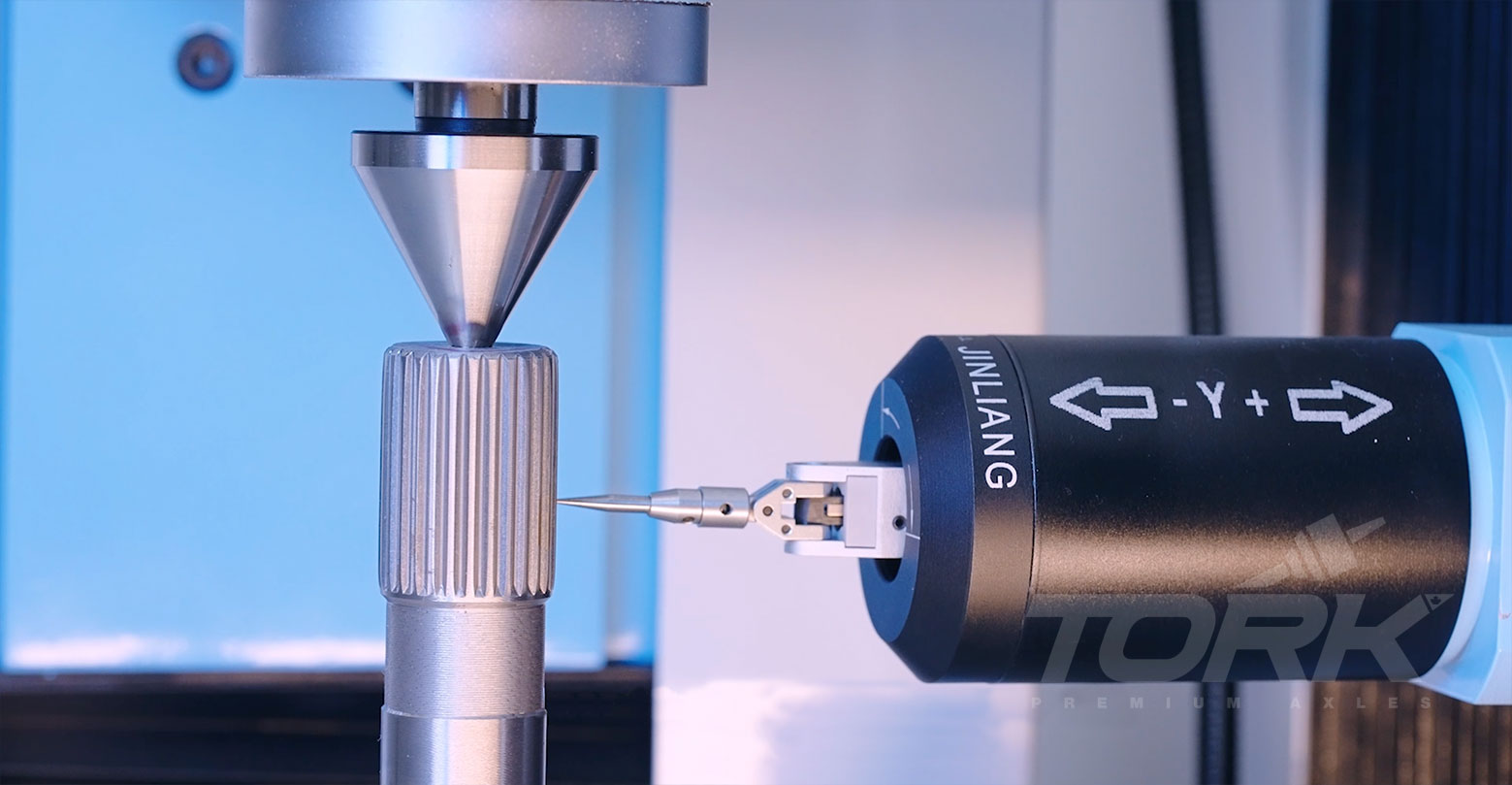

Our state-of-the-art manufacturing facilities and rigorous testing processes ensure that every axle meets our exacting standards, resulting in fewer returns and reduced downtime for our customers. Additionally, our competitive pricing and responsive customer service make us an attractive choice for fleets and vehicle manufacturers seeking reliable and cost-effective solutions.

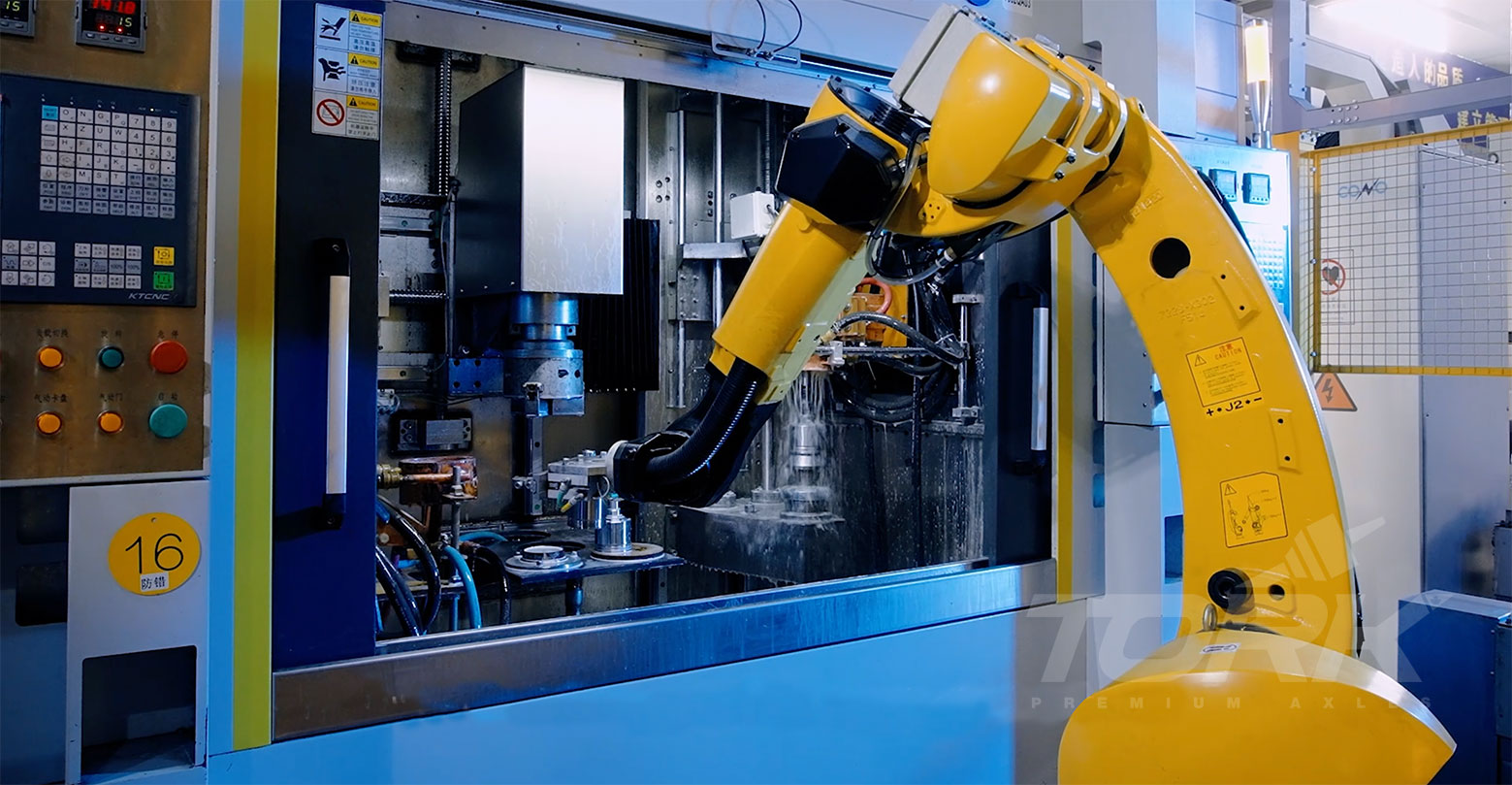

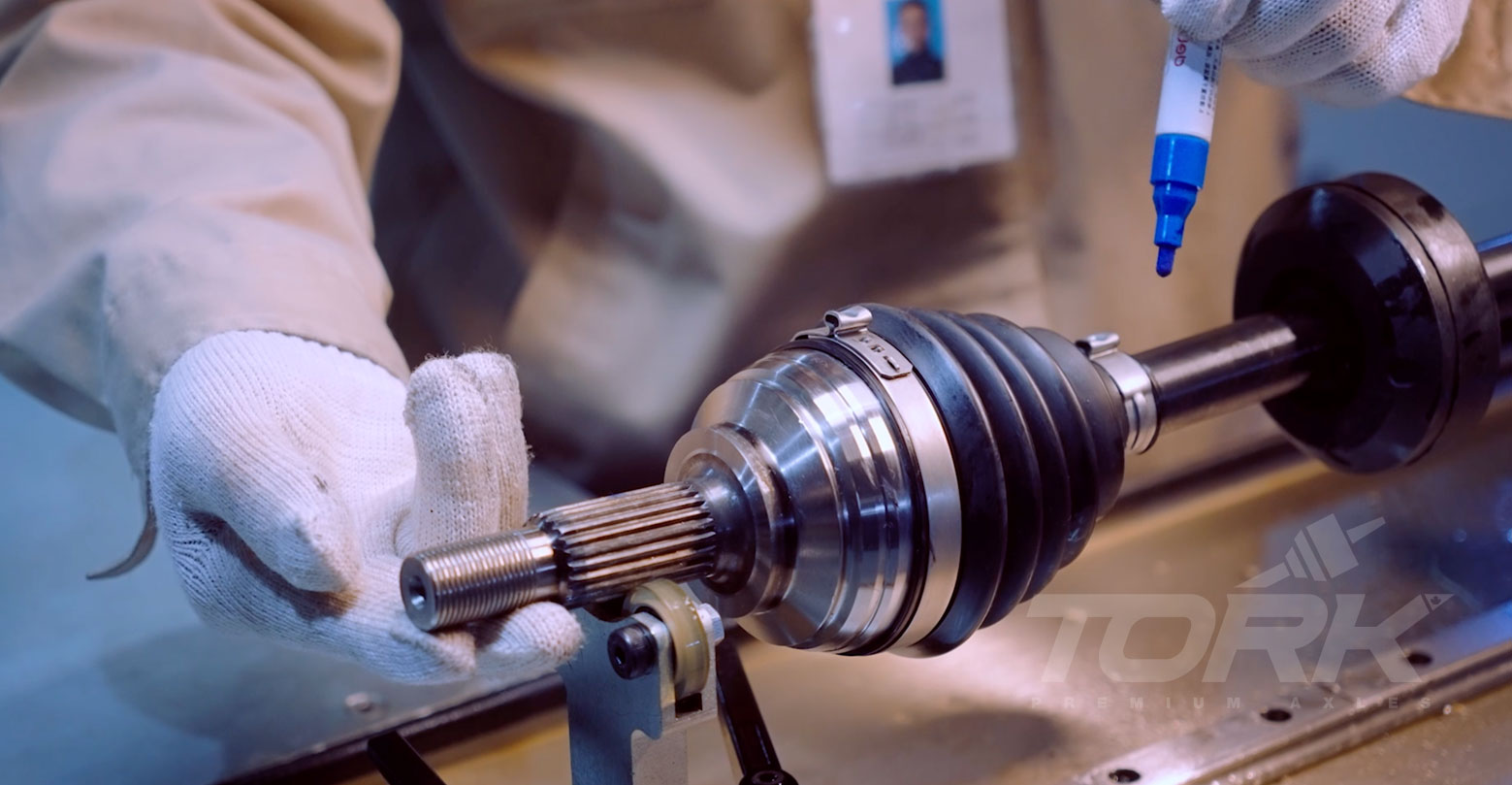

Manufacturing Process is controlled by TORK from beginning to end

At TORK, we have complete control over the production process of our CV Joints, enabling us to optimize quality, efficiency, and cost. This allows for consistent product quality, reduced defects, and improved reliability, as well as the ability to make adjustments to the production process in real-time.

Additionally, controlling the entire process allows us to implement lean manufacturing techniques, reduce waste, and optimize supply chain logistics, resulting in increased efficiency and reduced costs.

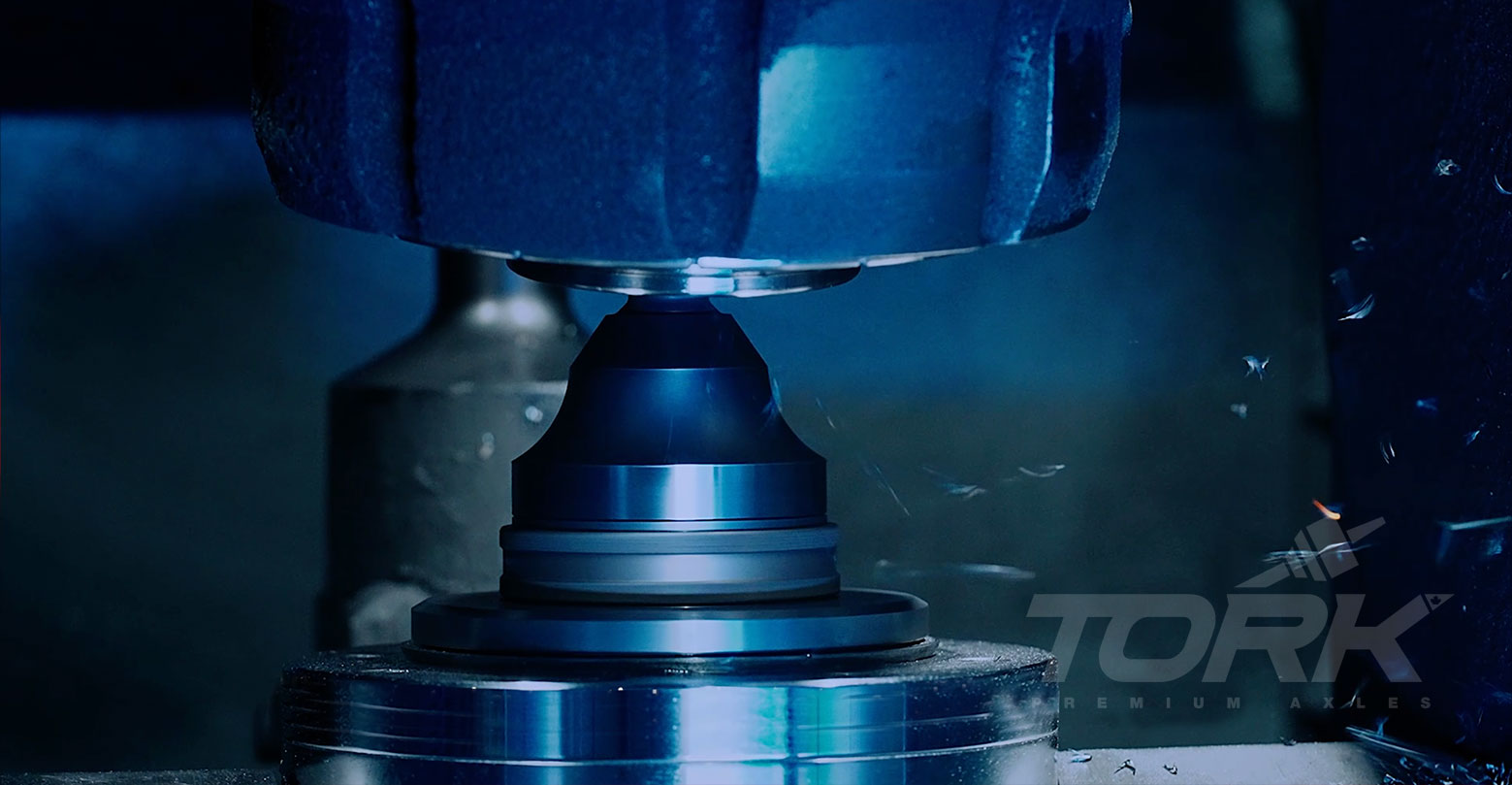

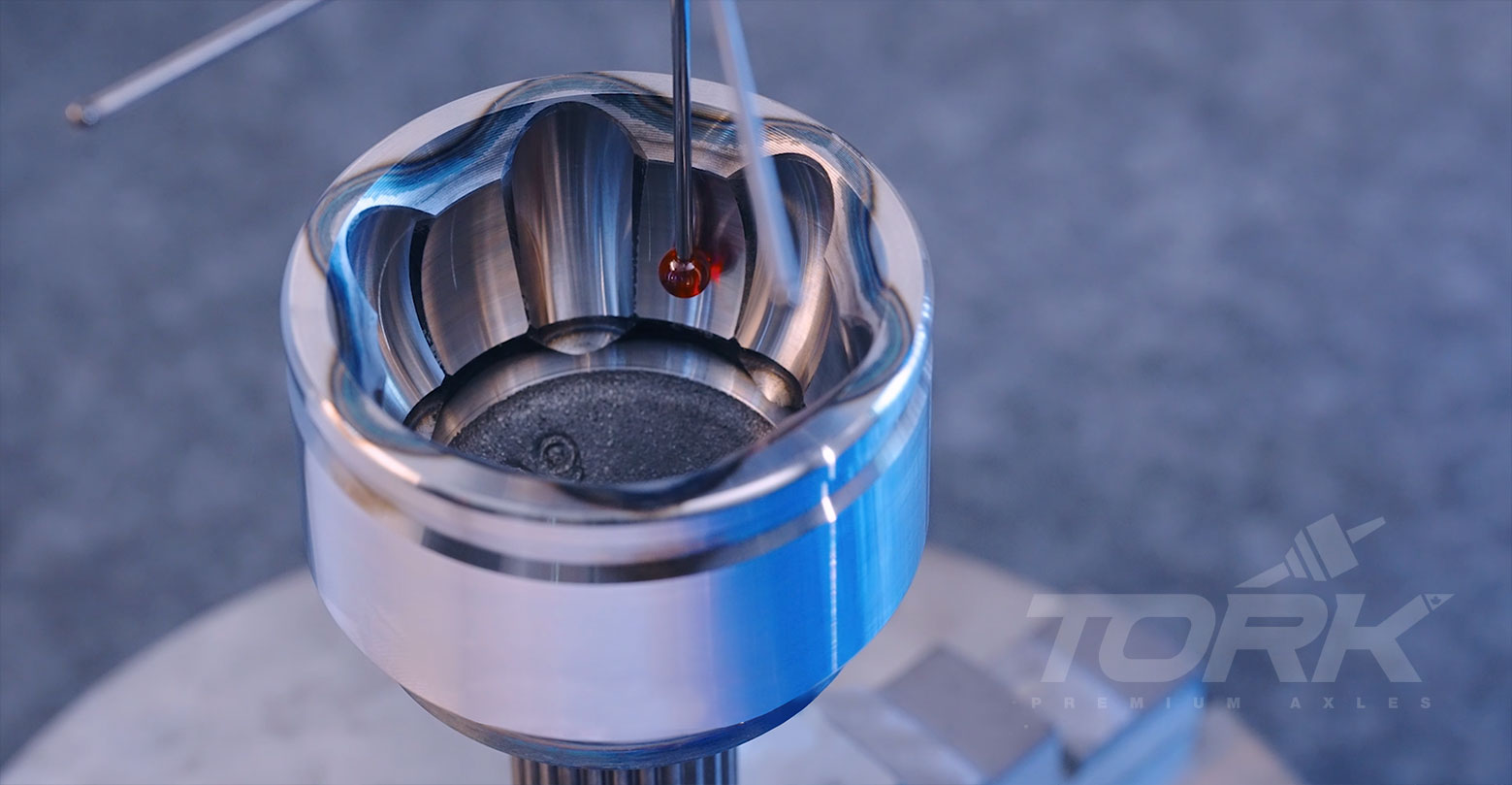

Our CV Joints Are Forged, not cast

This allow details such spline and threads to be done in one single process assuring 100% alignment.

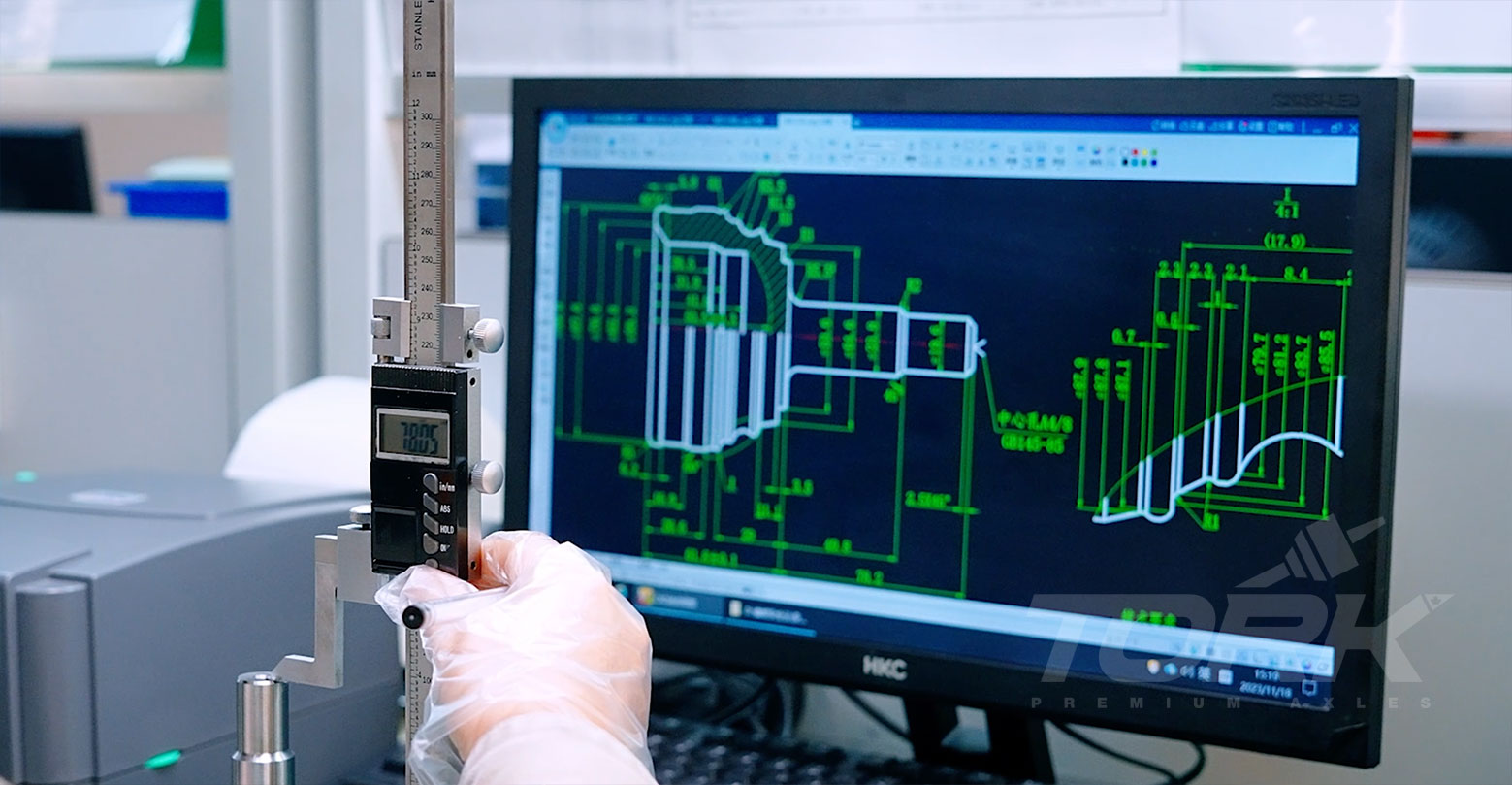

At Tork, we make sure we inspect what you'd expect... Always!

What is the advantage of having Forged Parts?

The advantage of forged auto parts is that they offer improved performance, durability, and reliability compared to cast or machined parts. Forging a part involves shaping metal through a process of edging and pressing, which allows for the creation of complex geometries and high-stress areas that can withstand increased loads and stresses.

This results in parts that are stronger, lighter, and more resistant to fatigue and failure, making them ideal for high-performance applications, racing, and heavy-duty use.